Brookhaven National Laboratory

Just what does it take to unlock a whole new generation of science and technology? That was the question Brookhaven National Laboratory (BNL) asked when the time came to design a replacement for the National Synchrotron Light Source (NSLS) – one of the world’s most widely-used scientific facilities.

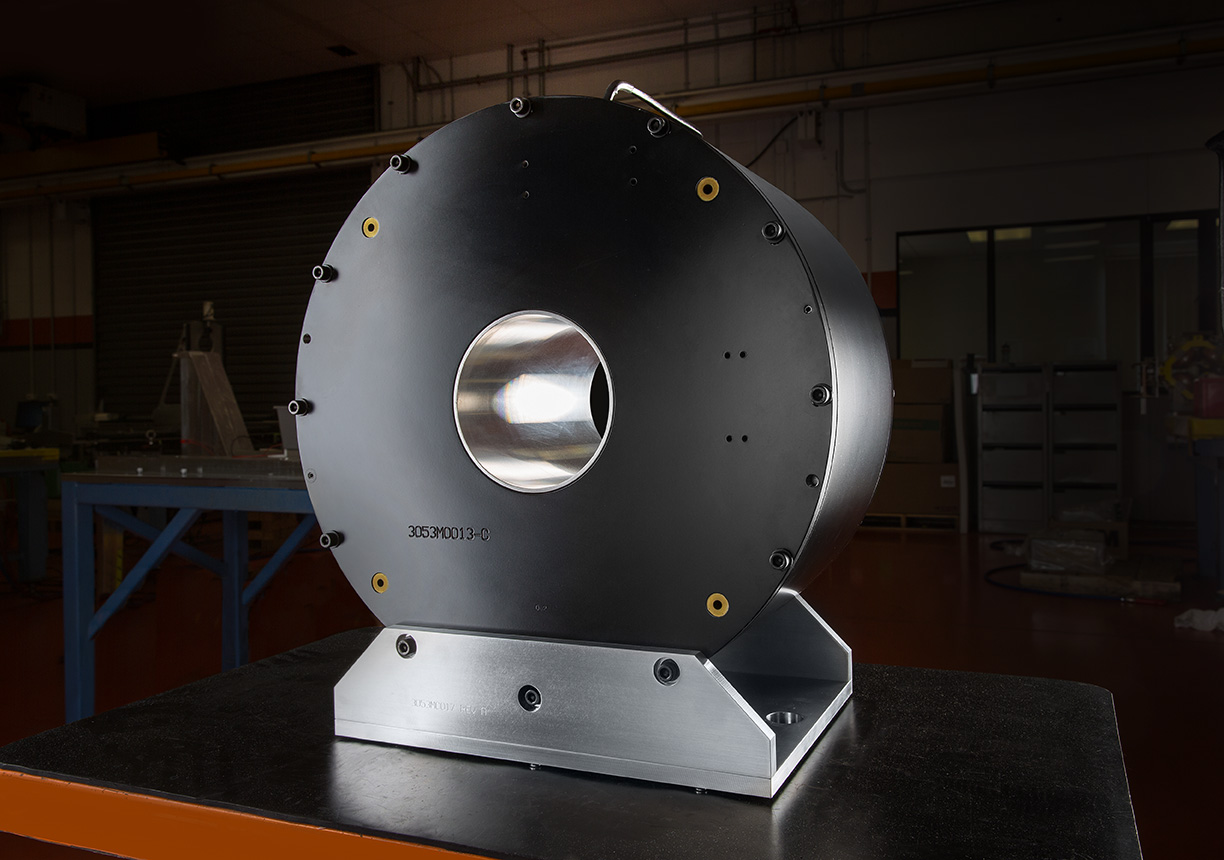

Brookhaven National Laboratory solenoid magnet

Every year, more than 2,400 researchers travel to Upton, New York to conduct experiments using synchrotron radiation - the intense beams of light produced by the NSLS facility - to probe deeply into the very materials and structures of our world.

For three decades researchers have, and still, use the NSLS to extend the limits of human knowledge in biology, physics, chemistry, geophysics, medicine, and materials science. It has contributed to thousands of scientific papers, and two Nobel Prize-winning breakthroughs.

When BNL started planning a replacement for the NSLS, their designers were seeking a stepwise improvement of the key parameters of synchrotron light sources to accommodate its more than 2,000 annual users. With that directive in mind, an ambitious $900 million project was born: the NSLS-II - a 792-meter storage ring operating at 3 billion electron-volts and producing light 10,000 times brighter than its predecessor.

Simply put: the world's most advanced synchrotron light source.

A trusted partner

With over 35 years of experience manufacturing electromagnets and particle accelerator systems, Buckley Systems was one of the few companies anywhere in the world that had the depth of experience required to produce electromagnets to the exceptionally high standard that would be required by BNL.

Our remit was to provide magnetic modelling, engineering, prototyping, production innovation, magnetic characterization, testing and quality control support for the project.

Electromagnetic modelling and prototyping

Buckley Systems was the vendor chosen for all of the high precision quadrupole and sextupole magnets, as well as the storage ring dipoles. To achieve the world’s lowest emittance beam, NSLS-II had stringent requirements for low harmonic content. Our magnet designers first validated reference designs using Vector Fields’ Opera electromagnetic FEA codes. This gave peace of mind that the multipole errors of the final product would be consistent with the lattice design.

Over a matter of months, Buckley Systems developed mechanical designs and manufacturing drawings for the project, paying special attention to manufacturability, accuracy and repeatable assemblies. Then, prototypes of each magnet class were built. Throughout the entire engineering and prototyping phase, we implemented design changes — improving, for example, the stability of field quality with current.

Manufacturing innovation

Traditionally, laminated multipole magnets are manufactured by die-stamping sheets of steel, then stacking and bonding individual magnet parts. The tolerances of the final assembly are largely an accumulation of stacking errors, lamination size errors and interface errors. The NSLS-II, however, demanded a higher level of precision, so Buckley Systems innovated.

First, the expensive die tool was discarded and replaced with a rapid CNC laser cutting process, which allowed for very cost-effective prototyping and very fast design changes.

Next, magnets were bonded and assembled with allowances on critical surfaces. We invested in advanced electric discharge machining capabilities, allowing the pole and fiducial features of a magnet assembly to be machined in a single operation, halving achievable tolerances and decreasing tooling cost while ensuring flexible and responsive manufacturing.

Volume manufacturing

Over 18 months, Buckley Systems manufactured a production run of 150 storage ring magnets. Throughout this process our team worked closely with our BNL counterparts, maintaining repeatability and tolerances (every one of the 54 dipoles had a 5-micron gap uniformity over their 2.6m length) and proving the efficacy of the novel production techniques developed throughout the process.

World-class magnetic measurement

Buckley Systems has a dedicated magnetic measurements team that fully test every magnet. Rotating coil equipment was custom-built in a dedicated, temperature-controlled lab, which was then used to verify the magnet design, fine tuning the harmonic content of each multipole with mechanical shims and ensuring the highest possible quality control. Harmonic content was measured to the 22nd order and down to parts-per-million of the fundamental.

First light

NSLS-II achieved “First Light” on October 23, 2014. Experiments are underway. As with our involvement in other synchrotron projects (including the NSRRC Taiwan Photon Source) Buckley Systems is proud to have partnered with Brookhaven National Laboratory on this seminal project.